OEM Massager Sampling: How to avoid Quality Fade in bulk orders?

- By Grace

- Updated on

You’ve seen it happen, haven't you? A massager electric supplier sends that perfect "golden sample." It looks, feels, and works exactly like you wanted. But then the nightmare begins. Months later, your bulk massager order arrives with patchy quality, unexpected failures, and a list of problems that puts your brand's reputation on the line. This disaster, called "Quality Fade," is a costly gamble you can't afford when you import massager electric products.

Here at KLCOSY, a leading China massager factory, we see things differently. A sample isn't just a product preview; it's a complete audit of the manufacturing process itself. Our sampling system for every portable massager is built on a foundation of total transparency, designed to give our B2B partners unshakeable confidence that the quality they sign off on is the quality they'll get in every single shipment. This isn’t about just sending you a personal massager. It’s about proving our commitment as a long-term massager electric manufacturer to a predictable, risk-managed supply chain.

So, let’s pull back the curtain on how we handle sampling for any custom massager electric. I'll walk you through how we validate our process, the different pathways you can take, how the costs work, and how we handle revisions together.

What Does Our Sampling Process Really Validate?

Tired of suppliers who are obsessed with a sample's looks but ignore the process integrity needed for mass production of massage devices? That's the shortcut to future quality headaches.

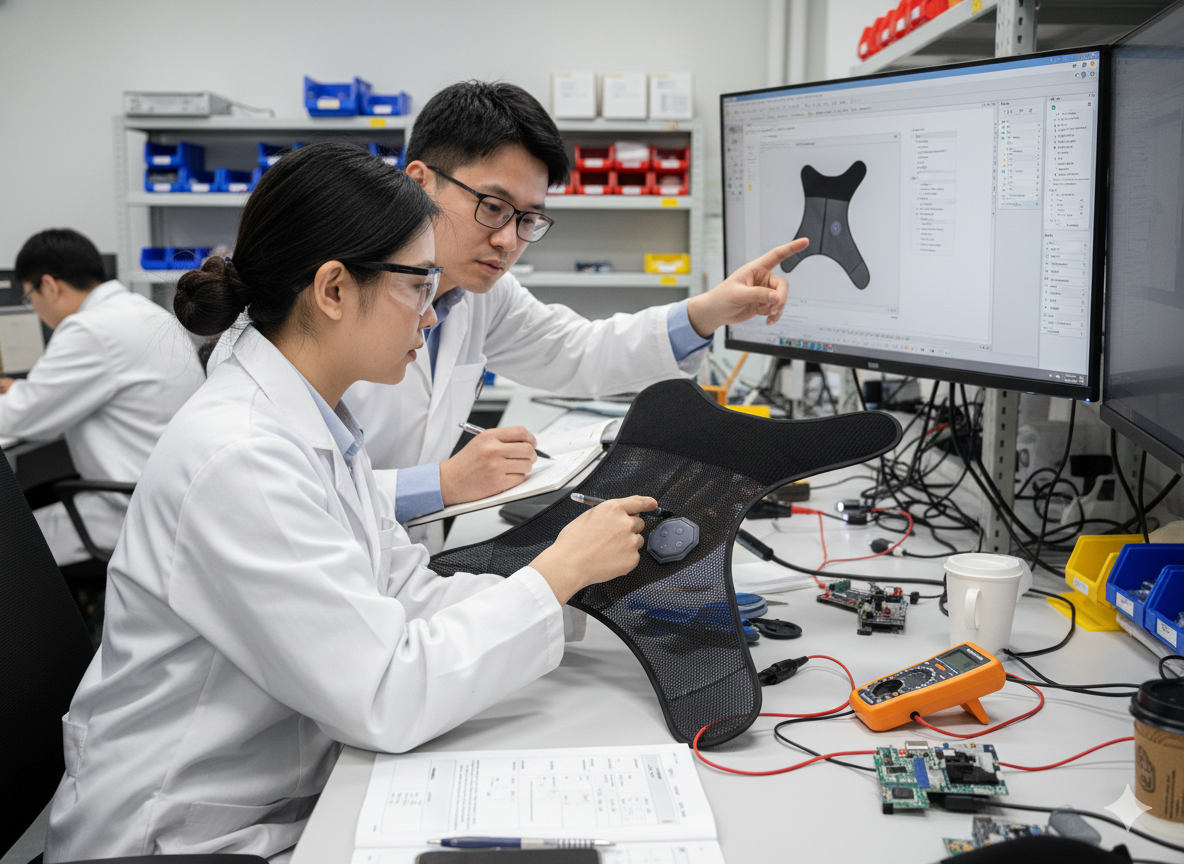

I remember a conversation with a German distributor. He told me our incredibly detailed validation process, which included full material certifications, was the single reason he chose us as his Chinese massager supplier. It was proof we could deliver consistency at scale. Our entire philosophy is built on this: a successful sample from a massager factory is the direct result of a stable, repeatable system.

Bottom line? Our sampling procedure is a tough, no-nonsense validation of three critical pillars. First, Process Capability. We confirm our manufacturing line can build your heat massager or vibrating massager orAip pressure massager or red light massager to spec, over and over again. This is where we hunt down potential bottlenecks before they become expensive problems. Second, Material Integrity. We guarantee that every component—from the motor down to the fabric—is sourced from our vetted suppliers and passes our strict quality control. This transparency in our Bill of Materials (BOM) is what prevents "component fade," that sneaky trick where cheaper parts are subbed in later. Finally, Manufacturability. Our engineers run a Design for Manufacturability (DFM) analysis to make sure your design is built for efficient, high-quality production. It's this system-level validation that truly de-risks your investment in massage equipment.

Which Sampling Pathway Is Right for Your Business?

Does the idea of creating a custom body massager feel overwhelming? It’s a common roadblock. Many businesses struggle to find a partner who can handle their specific needs, whether it's a simple white label massager electric or a brand-new design from scratch.

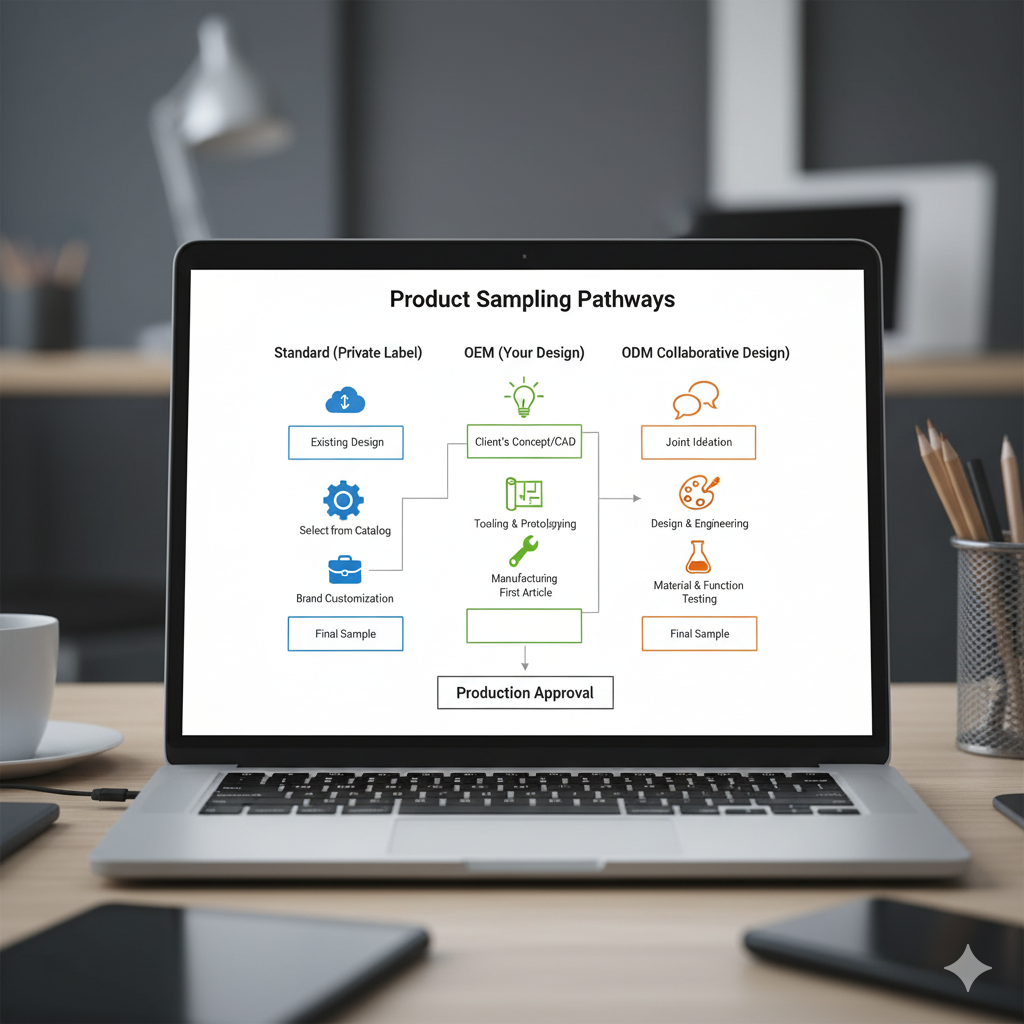

We've structured our sampling process into three clear pathways to match your business goals:

- Standard (Private Label): The fastest and most cost-effective route.

- OEM (Your Design): For clients with a complete product blueprint.

- ODM (Collaborative Design): A full partnership from concept to creation.

A retail brand owner I worked with recently shared that our OEM massager electric pathway was a game-changer for them. They handed us the design, and we delivered a production-ready sample in 15 days, getting them to market right on schedule. That's the kind of support we're talking about.

Choosing the right path is crucial. Our Standard (Private Label Massager) Sampling is perfect for those looking to export massager electric products quickly. You pick a proven model from our catalog, and we add your branding. The OEM massager pathway is straightforward: you provide the technical specs, and we become your expert manufacturing arm. The most comprehensive tier is our ODM massager Service, where we act as your in-house R&D team to engineer a unique massage machine that carves out its own space in the market.

How Are Wholesale Massager Sample Costs and Lead Times Calculated?

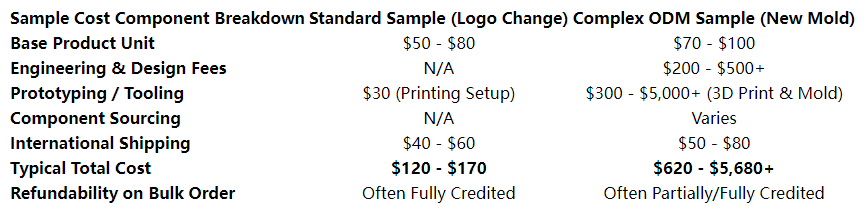

So, what’s the price tag on this peace of mind? If you've ever paid a steep sample fee without a clear breakdown, you know how frustrating it can be. Vague costs and timelines create uncertainty when you're sourcing wholesale massage products. We don't operate that way.

The founder of a wellness startup was worried about the initial investment for their ODM massage device. He was relieved when we showed him how the fee, which covered 3D modeling and component sourcing, would be credited towards his first wholesale body massager order. It's how we build partnerships.

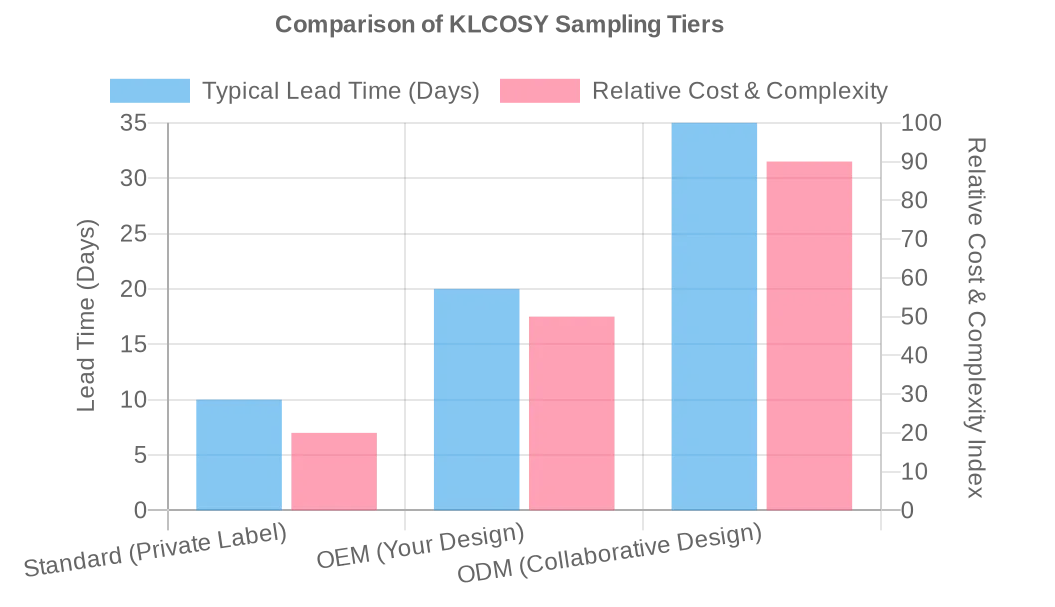

Let's break it down. Costs and lead times aren't arbitrary; they are directly tied to the project's complexity. A simple logo on a cordless massager might only take 7-10 days. A full ODM project? That could be 30 days or more. The cost simply reflects the resources involved: engineering hours, 3D prototypes, material sourcing, and maybe even mold creation for complex OEM or ODM projects. We give you a detailed cost breakdown before we start. And for our long-term partners, we often credit that sample fee right back to your first mass production order. It's a shared investment in success.

What Happens If My Custom Massager Sample Needs a Tweak?

What if that first sample isn't quite right? A rigid, "take-it-or-leave-it" revision process from your massager supplier can kill a great project. We don't see feedback as a problem; we see it as a critical part of getting it right.

A clinic partner in Australia, for instance, needed a change to the air compression intensity after testing their first body massager australia sample. Think of it like tailoring a suit—the first fitting is rarely the last. Our engineering team delivered a revised sample with updated firmware in just 7 days, ensuring the final product met their therapeutic standards perfectly.

Our goal is to deliver that "golden sample" that becomes the definitive standard for mass production. It’s an iterative process. Once you get your sample, your account manager schedules a technical debrief to get your detailed feedback. If it needs adjustments, our engineers map out the fastest path to revision. For minor changes, like a firmware update, we can have a new sample on its way in 5-7 business days. For bigger changes needing tooling adjustments, we'll give you a clear quote and timeline. This collaborative loop continues until you hold the final full body massager in your hands and say, "This is it."

The KLCOSY Sample Revision Process

Step 1: Client EvaluationYou test the sample against all functional, aesthetic, and quality specs.

Step 2: Structured FeedbackProvide detailed feedback to your dedicated KLCOSY account manager.

Step 3: Engineering ReviewOur technical team analyzes the feedback and proposes a clear action plan.

Step 4: Revision & ProductionWe produce a revised sample (T2, T3, etc.) with the approved changes.

Step 5: Final ApprovalYou sign off on the final "golden sample," authorizing mass production.

Conclusion

Our sampling process is more than a transaction; it's the first step in a transparent, long-term manufacturing partnership with a trusted portable massager manufacturer. By validating our process, offering tailored pathways, and maintaining a collaborative feedback loop, we turn sampling from a potential risk into your ultimate quality assurance tool for all massage products.