Design for Manufacturability (DFM): A Guide to OEM Product Launch

- By Grace

- Updated on

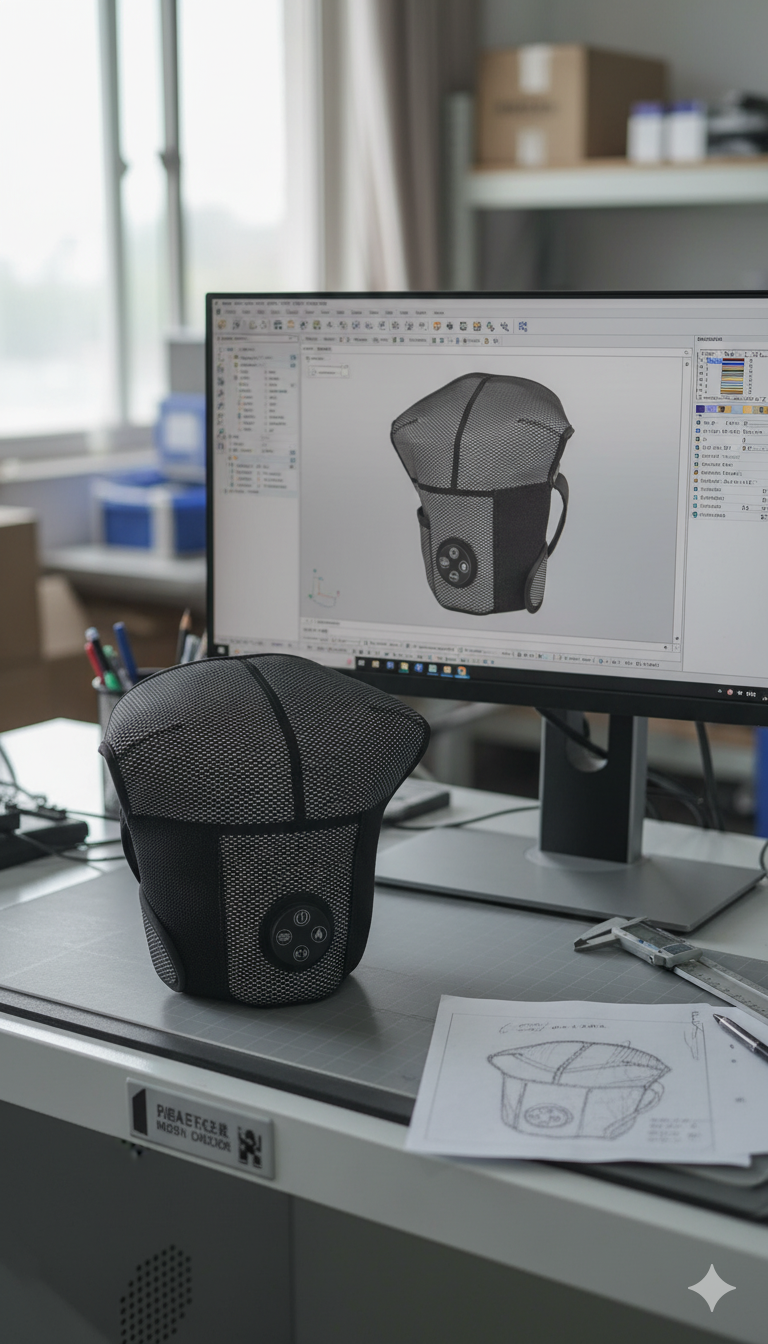

Your OEM design is complete. The CAD file is a perfect, digital representation of your vision. But here's the hard part, the part where most projects fail: turning that flawless file into tens of thousands of flawless physical products. A design that is 99% perfect on-screen can cause 100% of a project's delays and cost overruns if it's not optimized for the real world of manufacturing.

I've seen brilliant designs lead to absolute manufacturing nightmares—all because the crucial step of Design for Manufacturability (DFM) analysis was skipped. DFM isn't a formality; it's the single most important bridge between your blueprint and a successful reality. It's the first and most critical step in our engineering partnership, designed to save you money, time, and protect your brand's quality from day one.

In this guide, I'm pulling back the curtain on our comprehensive DFM process. I'll show you how we identify the hidden risks in your OEM massager design and provide specific, actionable solutions to ensure your product launch is on-time, on-budget, and built to the highest quality standards.

So, Why Does a "Perfect" Design Fail in Production?

You’ve invested hundreds of hours perfecting your design. It looks sleek and functions perfectly in the prototype. Yet, your first off-the-line samples are plagued with cosmetic flaws like sink marks, warping, or internal stress points that lead to cracking down the line. What happened?

The physics of molding plastic are unforgiving. I remember an OEM partner came to us after their previous supplier produced samples with visible sink marks over every single internal screw boss. Their design was beautiful, but it ignored the fundamental rules of plastic flow and cooling.

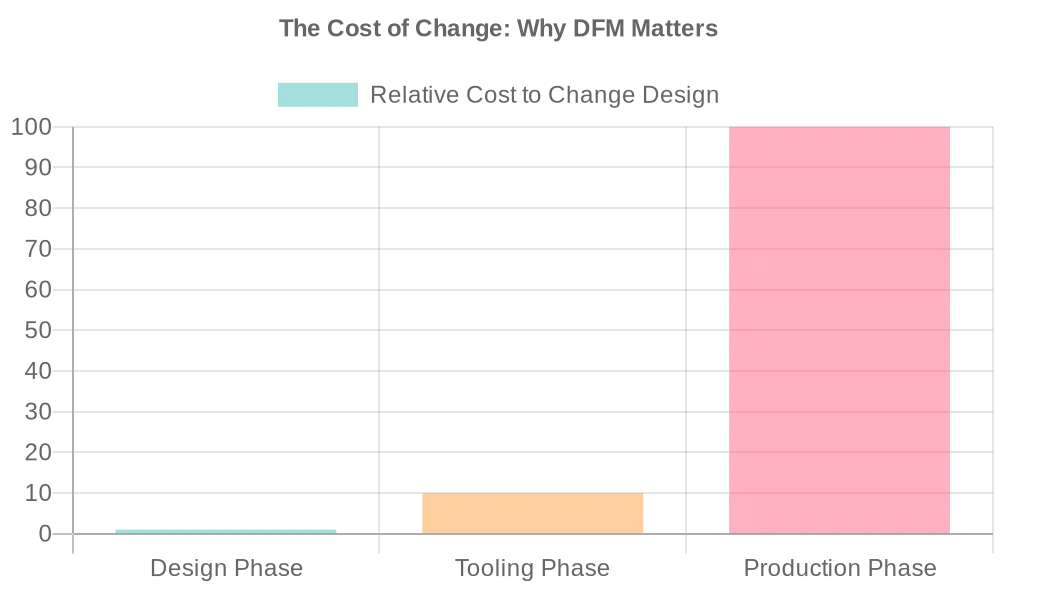

Think of it this way: injection molding involves shooting molten plastic under immense pressure into a steel cavity. As this plastic cools, it shrinks. If a design doesn't account for this with things like uniform wall thickness and slight tapers on the walls (draft angles), the result is a cascade of predictable defects. These aren't random mistakes; they are the guaranteed outcomes of a design that isn't optimized for the process. The cost of preventing molding defects *after* the mold has been cut is astronomical compared to making a simple tweak in a CAD file.

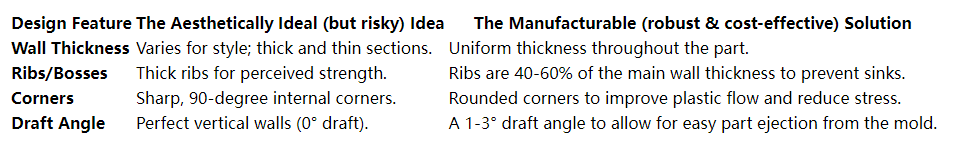

The 'Perfect' Design Idea vs. The Manufacturable Reality

A small change in the design phase can save thousands of dollars and weeks of delays. This is the entire purpose of a DFM analysis for injection molding.

what is a DFM report and What Should You Demand to See?

Let's be clear: a two-page "DFM report" from a potential supplier with a few generic comments like "check wall thickness" isn't an analysis; it's a checkbox. A true DFM is a detailed engineering document that provides immense value and is your manufacturing blueprint.

The lead engineer at a medical device company told us our DFM report was more thorough than their own internal review. We identified a critical mold flow issue that would have compromised their part's structural integrity, saving them from a potential product recall.

A world-class DFM report is a deep, multi-faceted analysis. It should be several pages long, rich with annotated screenshots of your own model, and have clear, data-driven recommendations. The cost of making a design change skyrockets exponentially once the mold is being fabricated. Our DFM is designed to solve all these issues at the cheapest and fastest point: the digital design stage.

Our report will always include:

- Core & Cavity Analysis: We identify the optimal parting line, suggest draft angles, and find any undercuts that would complicate the mold and add cost.

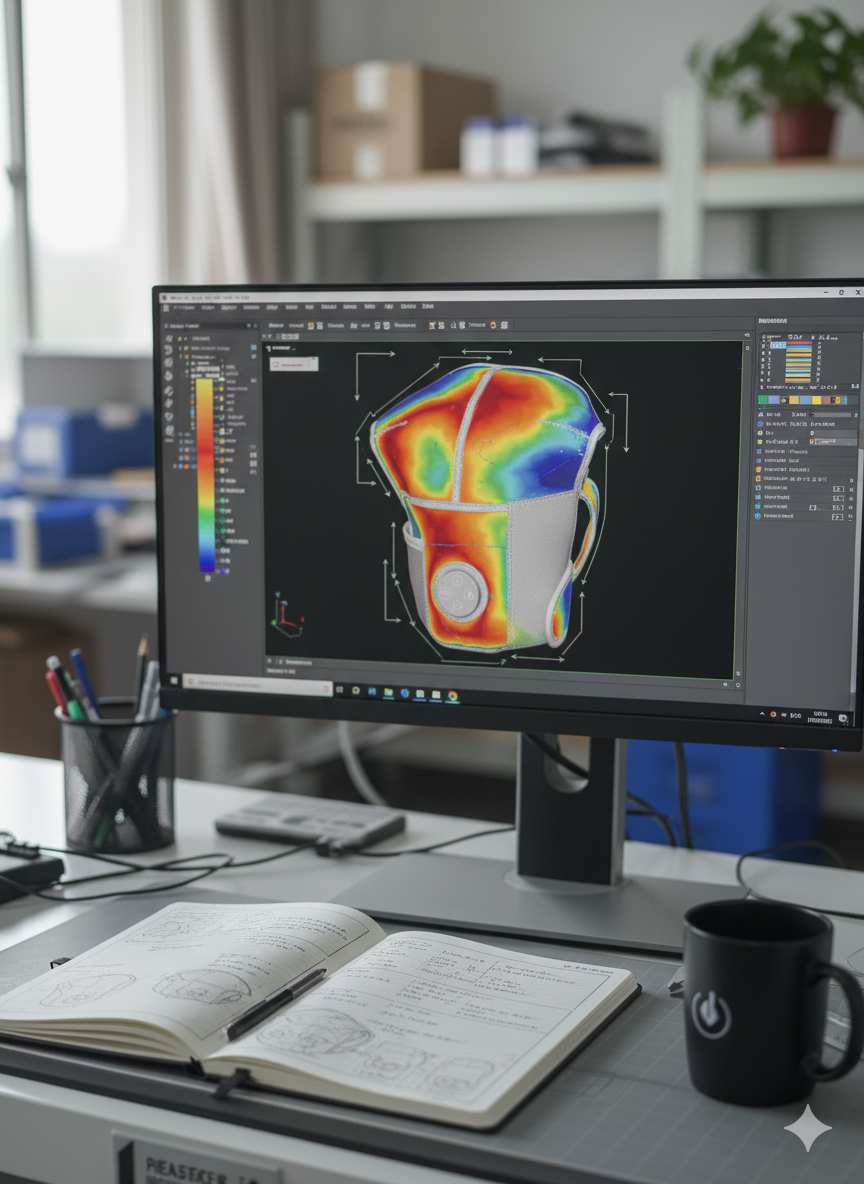

- Mold Flow Simulation: We use advanced software to simulate how molten plastic will flow into your mold. This predicts potential issues like weld lines and air traps, allowing us to optimize the gate location for a perfect part.

- Cost & Quality Optimization: We provide specific, concrete suggestions to improve your design, like a minor tweak to a rib that will eliminate a sink mark.

So, How Does the DFM Process Actually Work?

You're ready to move forward, but you're worried about sending your precious design files into a black hole and waiting weeks for a response, or getting stuck in a technical conversation lost in translation.

Our process is built on clear communication. A dedicated, English-speaking project engineer becomes your direct technical contact, guiding you through the findings and collaborating on solutions. A project manager for a smart home startup praised their dedicated KLCOSY engineer for not just finding problems, but for proposing three different solutions with clear trade-offs in cost and aesthetics.

We've refined our DFM process to be efficient and collaborative. It's a serious engineering review that is integrated into the total Non-Recurring Engineering (NRE) tooling fee. The DFM is a core part of the investment in a successful OEM product launch.

Our 4-Step DFM Workflow:

- File Submission & Kickoff: After you submit your 3D design files and place a tooling PO, we assign your dedicated project engineer.

- The Deep Dive Analysis (3-5 Business Days): Our engineering team performs the comprehensive analysis, including the mold flow simulation, and compiles the detailed report.

- The DFM Review Call: Your project engineer will schedule a video conference to walk you through the report page by page, explaining each finding and discussing potential solutions.

- Final Design Freeze & Sign-Off: Based on the review, your team makes the final revisions. We require your formal, written sign-off on the final DFM report and the updated design file. This "design freeze" is the green light for us to begin cutting steel.

This structured, collaborative process ensures there are no surprises. It transforms the start of manufacturing from a moment of risk into a moment of shared confidence.

A comprehensive Design for Manufacturability (DFM) analysis isn't an optional extra; it's the single most valuable investment you can make to de-risk your entire product launch. It is the blueprint for a successful partnership, ensuring your vision is transformed into a high-quality, manufacturable product, on time and on budget. We invite you to engage with our engineering team and experience a process built on transparency, data, and true collaboration.