Final Quality Control (FQC): A Guide to Preventing Massager Defects

- By Grace

- Updated on

A customer excitedly unboxes their new massager—your brand, your promise of quality—only to find it doesn't even turn on. That single "Out-of-Box Failure" (OOBF) does more than just trigger a costly return; it shatters brand trust and fuels the kind of one-star reviews that kill sales.

This nightmare scenario is almost always the result of a flawed final inspection process that relies on statistical sampling. The head of sourcing for a major electronics retailer told us our near-zero OOBF rate has saved them thousands in reverse logistics and preserved their customer review scores during peak holiday seasons. At KLCOSY, we’ve replaced the gamble of sampling with the certainty of 100% Final Quality Control (FQC)—a rigorous system designed to be the final, impenetrable gate that protects your brand.

In this guide, I'll detail the specific, comprehensive checks that every single one of your products undergoes before it's sealed in the box. I'll show you why sampling isn't good enough and how our meticulous FQC process ensures every customer's first experience with your product is a perfect one.

So, Why Did My "Passed" Shipment Still Have Defective Units?

You reviewed the pre-shipment report. It showed a "Pass" based on a standard AQL sample, giving you the green light to approve the shipment. Yet, you're still dealing with a steady stream of returns for defects that should have been caught.

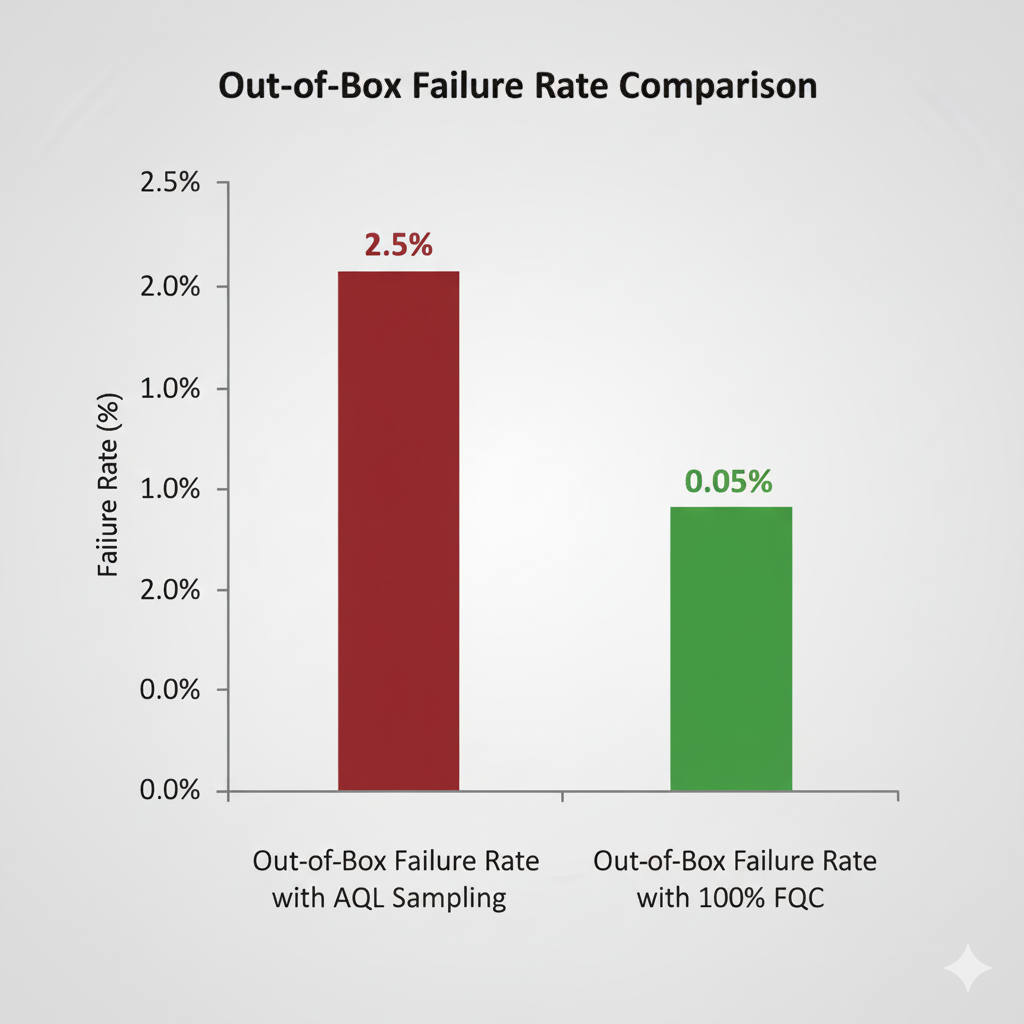

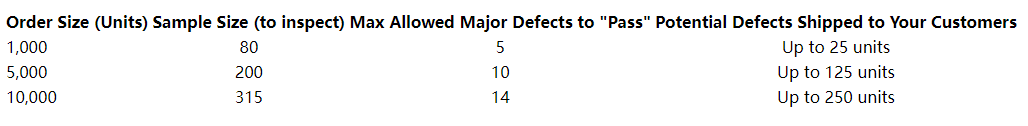

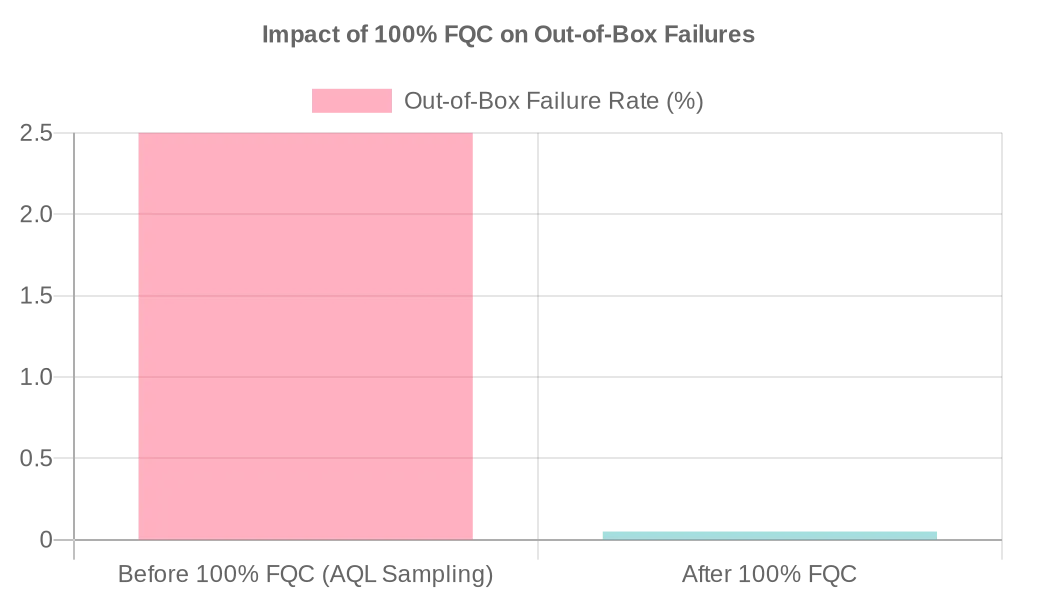

Here’s the problem: Acceptance Quality Limit (AQL) sampling isn't designed to find every defect. It's a statistical tool designed to determine if an entire batch is "acceptable" even with a known number of flaws. When you're in the AQL sampling vs 100% inspection debate, you need to understand what you're really agreeing to. A common AQL of 2.5 for major defects sounds low, but for a shipment of 10,000 units, it means the batch will be accepted even if it's likely there are up to 250 defective units within the entire order. For a brand whose reputation rests on every single unit, this is an unacceptable risk.

AQL 2.5: What It Actually Means for Your Shipment

This is precisely why we abandoned the industry standard in favor of a 100% inspection protocol. It is the only way to move from statistically *probable* quality to verifiably *certain* quality.

What Does Our '100% Inspection' Actually Entail?

It's a mandatory, three-phase final audit performed on every single unit by a trained inspector, covering function, aesthetics, and packaging. The manager of a luxury hotel chain shared that their biggest concern was a guest finding an incomplete package. Our meticulous massager final inspection on accessories ensures a premium, frustration-free experience every time.

Our FQC process is not a quick glance. It is a systematic procedure detailed in a product-specific massager inspection checklist that our team follows for every unit. Each unit's serial number is scanned and tied to its FQC report, creating a permanent, auditable record of its quality at the moment it was packed.

Phase 1: Full Functional Verification

Before anything else, we confirm the product works perfectly. Every single function is tested. This includes powering the unit on and off, cycling through every massage mode and intensity level, verifying that heating elements reach the correct temperature, and testing all safety features like the auto-shutoff timer. Any unit that fails even one of these checks is immediately rejected.

Phase 2: Meticulous Aesthetic Review

With function confirmed, the inspector performs a detailed 360-degree cosmetic check under bright, controlled lighting. Using the approved "golden sample" as a reference, they inspect for any aesthetic flaws—scratches, dents, or discoloration—and check for proper alignment of seams and gaps.

Phase 3: Complete Packaging & Accessory Audit

Finally, we verify the "whole product." The inspector ensures the correct user manual (in the right language), charging cable, and all included accessories are present and correctly placed in the packaging. They confirm all protective films are applied before the box is sealed.

So Who Signs Off on Quality, and How Is It Documented?

A process is meaningless without accountability. Who has the final authority to say a product is ready to ship to you, and what evidence can you review to trust their judgment?

The final sign-off is given by a dedicated FQC Team Lead, a specialist whose sole responsibility is to uphold quality standards. This sign-off is a digital entry in our quality management system, linking them to the FQC report for that specific production run. A corporate wellness manager told us that the detailed FQC reports we provide for each shipment give them the documentation they need for their internal safety and asset management audits.

Our FQC Team Leads are independent quality professionals who report directly to our Head of Quality Assurance. Their compensation is tied to quality metrics, not production volume, ensuring their objectives are perfectly aligned with yours. The comprehensive FQC report, including a summary of units inspected and any issues found, is archived and available upon your request, giving you a fully transparent window into the final quality of your order. This is a cornerstone of any serious private label massager QC.

The final quality check is our last opportunity to honor our commitment to you and our final promise to your customers. By rejecting the uncertainty of sampling and implementing a rigorous 100% FQC system, we ensure that the product you ordered is the product you receive—perfect, complete, and ready to build your brand's reputation. A commitment to this level of massager quality assurance is how we prevent massager defects and build long-term partnerships. We invite you to review the specific FQC checklist we’ve developed for your product.