The Ultimate Guide to Choosing a Foot Massage Machine

- By Grace

- Updated on

Ready to tap into the high-demand wellness tech market? 🌟 For e-commerce sellers and wholesalers, sourcing the right foot massage machine unlocks higher margins and customer loyalty—delivering not just a product but repeat purchases through proven relaxation, recovery, and retail appeal. We break down how top-tier massagers really work ( air pressure kneading, vibration, heat, and light therapy included ✨), so you can confidently stock, list, and scale in this booming global niche.

What is a Foot Massage Machine from a Manufacturing Perspective?

A foot massage machine is an electromechanical device engineered to simulate the techniques of manual foot massage, such as Shiatsu, kneading, and compression.

From an engineering standpoint, it is an integrated system of motors, mechanical actuators, air pressure systems, and a Printed Circuit Board Assembly (PCBA), all housed in an ergonomic chassis, typically made from injection-molded ABS plastic or silicone

Core Components of a Modern Foot Massage Machine

Understanding the internal components is crucial for evaluating Wholesale foot massage machine quality. Each part directly impacts performance, durability, and unit cost.

- Drive Motors: These are the heart of the machine. High-quality DC brushless motors offer longer lifespans, quieter operation, and more consistent torque for deep-kneading massage nodes.

- Massage Mechanism: This assembly includes theairbag assembly , Motor, heating and red light element. The material (e.g., silicone vs. hard plastic) and gear design dictate the massage experience.

- Air Compression System: Comprises an air pump and a series of air bladders (airbags). The quality of the pump determines pressure intensity, while the placement of the bladders targets specific areas like the instep and ankle.

- PCBA (Control Board): The "brain" of the device. A well-designed PCBA ensures precise control over massage modes, intensity levels, heat, and safety features like the auto shut-off timer.

- Heating Element: Typically a carbon fiber or PTC heating film. Key metrics are heat-up time and stable temperature control, managed by thermistors to prevent overheating.

- Housing/Chassis: The outer shell, usually made from durable ABS or Silicone. The quality of the injection mold determines the fit, finish, and structural integrity.

How Does a Foot Massage Machine Work? The Engineering Behind Relaxation

The device operates through a coordinated sequence controlled by the PCBA.

Upon selecting a mode and intensity via the control panel or remote, the main PCB processes the command and coordinates all functional components. Drive motors activate the massage mechanism to perform programmed kneading patterns along the soles, while the air pump system rhythmically inflates and deflates airbags to enhance blood circulation through compression.

The system simultaneously engages auxiliary therapies: the heating element warms to 40-65°C for muscle relaxation, red light modules emit precise 650nm/850nm wavelengths through constant-current drivers, and vibration motors generate rhythmic oscillations through massage nodes. All components operate under integrated electronic control to ensure both therapeutic efficacy and user safety.

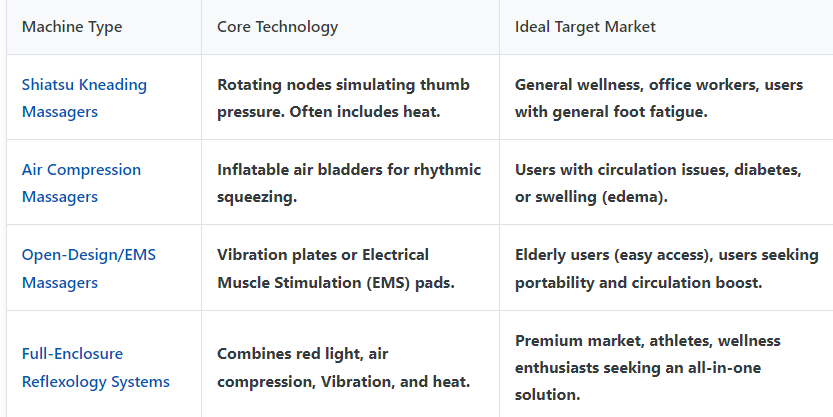

Types of Foot Massage Machines for Wholesale & Private Label

Selecting the right type of machine is critical for targeting specific market segments. Here are the primary categories available for bulk foot massage machine for sale orders.

How to Choose the Right Foot Massage Machine Manufacturer

Your choice of manufacturing partner will define your product's success. Look beyond the unit price and evaluate their capabilities holistically.

Strategic Decision: OEM vs. ODM foot massage machine

Your go-to-market strategy dictates whether you need an OEM or ODM partner.

- OEM (Original Equipment Manufacturer): Choose an OEM foot massage machine partner if you have a proprietary design and require a factory to execute your vision. This route offers maximum brand differentiation but involves higher NRE (Non-Recurring Engineering) costs and longer lead times.

- ODM (Original Design Manufacturer): Select an ODM foot massage machine solution to leverage the factory's existing, proven designs. You can customize the branding, colors, and packaging for rapid market entry with minimal R&D investment.

Evaluating Wholesale foot massage machine quality

A truly reliable manufacturing partner demonstrates quality through verifiable processes and documentation, including valid Design Patents that protect product appearance and Utility Patents covering technical innovations, along with essential market certifications such as CE, FCC, RoHS, and UL/ETL for target regions, while also maintaining full component traceability systems to ensure supply chain resilience and product accountability.

Why Partner with AuraRelax Technology?

As a vertically integrated foot massage machine manufacturer, we offer a distinct competitive advantage.

- In-House R&D: Our team of mechanical and electrical engineers provides expert support for both complex OEM projects and rapid ODM customizations.

- End-to-End Quality Control: We control every stage of production, from motor winding and plastic injection to final assembly, ensuring unparalleled reliability.

- Proven Global Partner: With a full suite of international certifications and extensive logistics experience, we provide a seamless supply chain from our factory floor to your warehouse.

- Scalable Production: Our state-of-the-art facility is equipped to handle orders from 500 units to 50,000 units, ensuring we can grow with your business.

Conclusion

Making an informed decision on a foot massage machine requires more than a catalog review; it demands an understanding of the technology within. By evaluating components, understanding the engineering, and selecting a manufacturer with proven technical expertise, you position your brand for long-term success and profitability in the thriving wellness market.

Frequently Asked Questions (FAQ)

What is the difference between an OEM and ODM foot massage machine?

An OEM (Original Equipment Manufacturer) project is where you provide a 100% unique design and the factory builds it for you. You own the IP. An ODM (Original Design Manufacturer) project involves selecting a factory's pre-existing, market-tested design and customizing its appearance (logo, color, packaging). ODM offers a much faster time-to-market and lower initial investment, ideal for new entrants or diversifying product lines.

What are the most critical quality checkpoints for a bulk foot massage machine order?

Critical checkpoints include: 1) Motor Durability Testing (lifespan under load). 2) PCBA Stress Testing (ensuring electronic stability). 3) Material Safety (RoHS compliance for plastics and fabrics). 4) Power Adapter Certification (UL, CE, ETL). 5) Functional QC (ensuring all massage modes, heat, and intensity levels work as specified on every unit).

What are the benefits of using a foot massage machine for wellness programs?

Foot massage machines offer significant benefits by improving circulation, reducing muscle tension and stress, and alleviating foot pain associated with conditions like plantar fasciitis. For corporate wellness programs or healthcare promotions, they provide a tangible tool for employee or customer well-being, enhancing brand loyalty and demonstrating a commitment to health.