How Automated Manufacturing Prevents Quality Fade in B2B Supply Chains

- By Grace

- Updated on

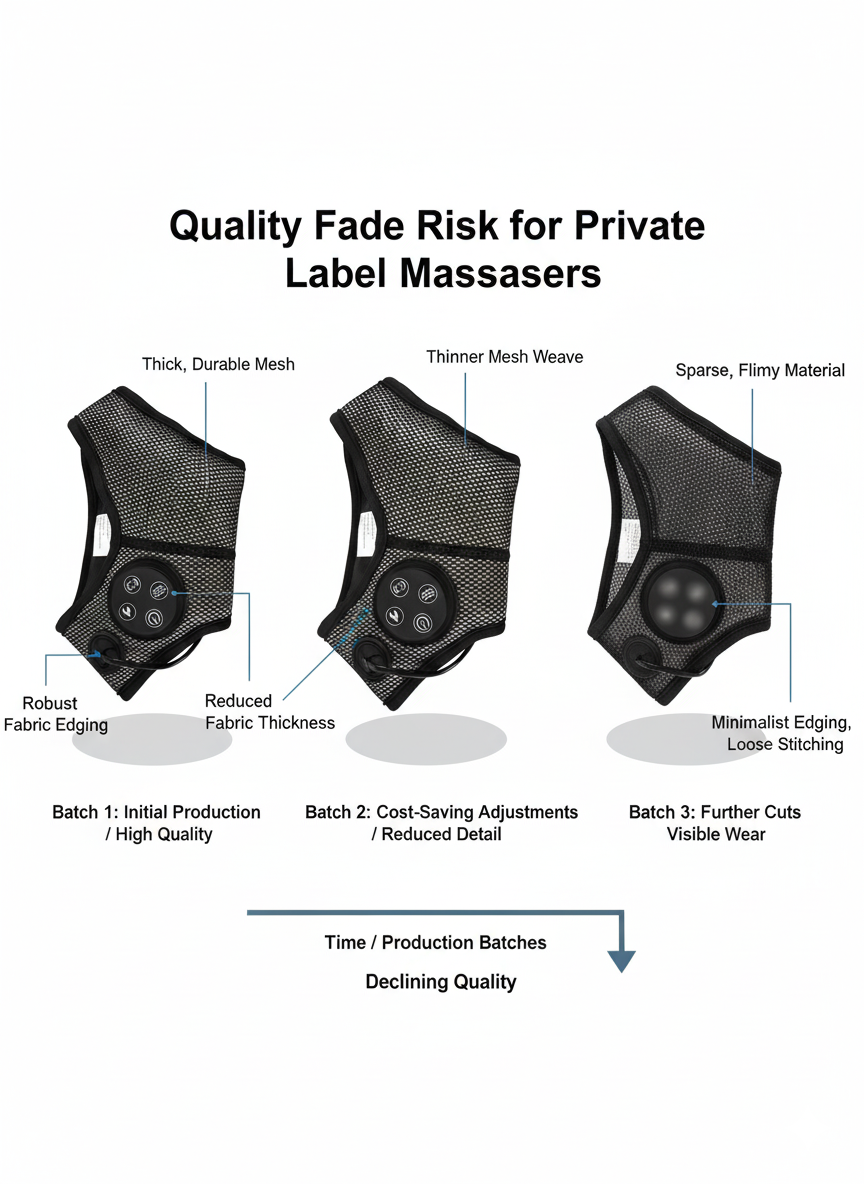

You’ve seen it happen, right? The first shipment is perfect, an exact match to that golden sample. But slowly, with each new order, you notice things are... off. The plastic feels a bit thinner, the motor has a different hum, and the customer complaints start to trickle in. This slow, sneaky decline in quality is known as "Quality Fade," and it’s a risk that can poison even the strongest B2B partnerships. The cost of these field failures isn't just about money; it’s about your brand's hard-won reputation.

As a dedicated massager manufacturer, we at KLCOSY have built our entire philosophy around stopping this problem before it ever starts. We don’t believe consistent quality is something you hope for or catch at the last minute; we believe it’s the non-negotiable result of a transparent, disciplined, and highly automated production system. Our Proactive Quality Assurance (PQA) framework is designed to give our partners the one thing they need most: supply chain reliability.

Look, this is about more than just selling massagers. It's about giving you a de-risked supply chain for your private label massagers that you can bet on, order after order. We’ve moved beyond hoping for quality to guaranteeing it through process control. In this article, I'm going to pull back the curtain and show you exactly how we do it.

Why Does Product Quality Decline After That Perfect First Batch?

It’s a frustratingly common story: you sign off on a flawless sample, only to find that the mass-produced units that follow slowly degrade. This isn't just bad luck; it’s a clear symptom of a weak manufacturing process and a major threat to supply chain reliability.

I remember a conversation with a German distributor who told us his biggest fear was "the slow poison of hidden changes." He'd been burned before by a supplier who secretly swapped to cheaper components to shave off costs, leading to a massive spike in warranty claims months down the road. Our solution was simple: we gave him a locked Bill of Materials (BOM) and a completely transparent change control process. That gave him the confidence that every single unit from our automated manufacturing line was identical to the first.

The Hidden Risk of "Quality Fade"

"Quality Fade" is the gradual, often invisible, degradation of a product's quality over successive production runs. It happens when a manufacturer, squeezed by cost pressures, starts making tiny substitutions—a cheaper material here, a simplified process there. While one minor change might fly under the radar, the cumulative effect can lead to catastrophic product failures. For distributors of B2B wellness products, this is a huge risk that leads to unhappy customers, a flood of returns, and long-term brand damage. The root cause is almost always the same: a lack of disciplined process control and transparency.

Moving Beyond Reactive Final Inspections

Many companies still rely on final inspections to catch defects. But here's the thing: that's a reactive, inefficient strategy. A final inspection only catches a problem after you've already spent the time, money, and materials to produce a faulty product. It does nothing to fix the root cause. Relying on this method is like trying to solve a traffic jam by only looking at the last car. A truly effective quality system—what we call proactive quality assurance—focuses on preventing defects from happening in the first place. It's about building quality into every single step, from raw material sourcing to final assembly.

How Automated Manufacturing Guarantees Rock-Solid Consistency

Are you worried that human error could create inconsistencies in your order? It’s a valid concern, and it's one we've systematically eliminated through advanced automated manufacturing.

A new online retail partner was drowning in high return rates from a previous supplier because their massagers performed differently from one unit to the next. They told us, "Our customers expect the same great experience every time." We showed them our automated assembly lines, where everything from soldering to torque control is handled by machines. We showed them how we build consistency into the DNA of the product. The result? Their return rate for our massagers is now under 1%, proving the tangible benefits of automated assembly lines.

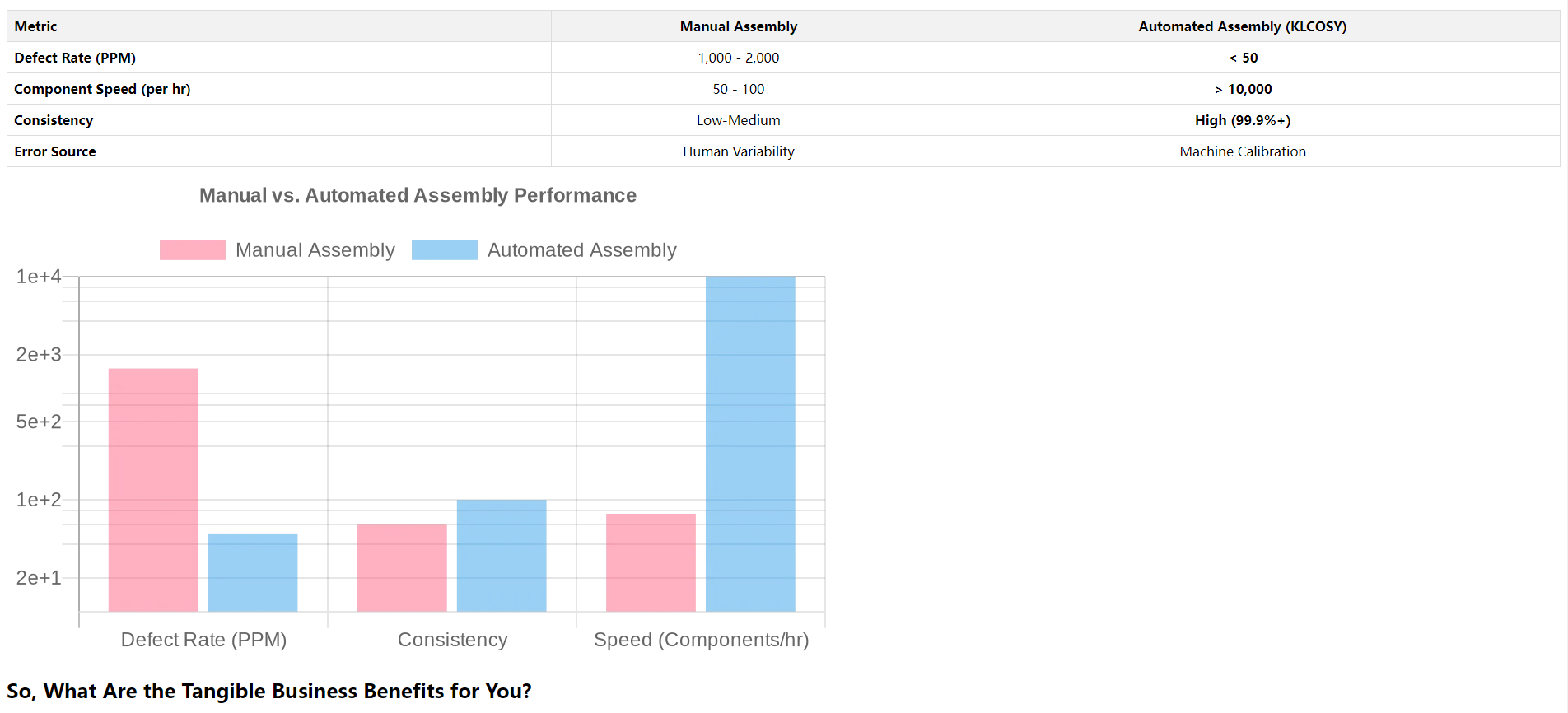

Robots Don't Have Bad Days: Eliminating Human Error

The primary role of automation in quality assurance is the near-total elimination of human error. It's that simple. Automated systems perform repetitive tasks like component placement, soldering, and fastening with a level of precision that’s impossible for a human to maintain over a long shift. For example, a robotic arm can apply the exact same amount of adhesive or tighten a screw to the precise torque spec thousands of times without the slightest deviation. This ironclad process control ensures every unit is built identically, leading to consistent performance you can count on.

Achieving Perfect Repeatability, Every Single Time

Great consistency comes from perfect repeatability. The Factory automation benefits this goal by ensuring every product goes through the exact same process under identical conditions. Our systems maintain precise control over critical parameters like temperature, pressure, and speed, which are monitored 24/7. This removes the variability that inevitably comes with manual labor due to factors like fatigue or distraction. The result is a highly stable manufacturing process that produces a uniformly high-quality product. This is exactly how to prevent quality fade in manufacturing and guarantee the thousandth unit is identical to the first.

Catching Deviations Instantly with Real-Time Monitoring

Unlike old-school manual inspection, our automated lines integrate quality control directly into the production process. Integrated sensors and machine vision systems monitor every stage of assembly in real-time. These AI-powered systems can spot microscopic defects, misalignments, or incorrect components instantly—far more reliably than the human eye. If a deviation is detected, the system can flag it or even stop the line immediately, preventing a single flaw from being replicated. This proactive approach helps us slash and reduce defect rates, ensuring only perfect products move to the next stage.