Massager Quality Fade: A Guide to Predictable Sourcing

- By Grace

- Updated on

You’ve approved the "golden sample," placed your first large order, and everything is perfect. But a few shipments later, the customer complaints start trickling in. The quality is slipping. The motor sounds different. The battery doesn't last as long. This, my friend, is "Quality Fade," a silent profit killer that erodes brand trust and can cripple a growing business.

I've seen this story play out countless times in our industry. The root cause isn't a single bad batch; it's a systemic failure in a supplier's manufacturing process. At KLCOSY, we’ve built our entire operation around a transparent, process-driven framework designed to eliminate this risk entirely. We don’t just sell massagers; we deliver a predictable, reliable massager supply chain you can build your business on.

In this guide, I'll break down the exact systems we use to ensure the hundredth batch is identical to the first, and show you how our Proactive Quality Assurance (PQA) system provides the verifiable consistency you need for successful private label massager sourcing.

Why Does "Quality Fade" Silently Destroy Your Bottom Line?

The problem is that you've invested heavily in marketing and building your brand, only to see your profits get eaten alive by returns and negative reviews. The initial quality that won you over has mysteriously vanished, and your supplier has no clear answers.

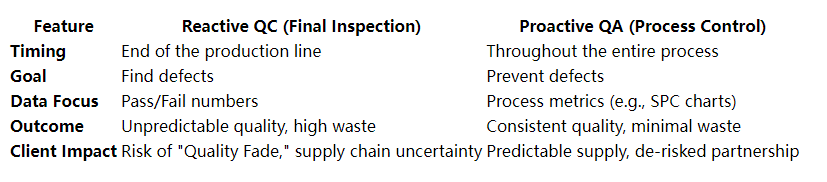

This happens because of a reactive, inspection-based mindset, where quality is only checked at the very end. It's a fundamental failure of process control. I remember talking to an online retail partner who told us that our product's incredibly low defect rate cut their returns in the massager category in half. They went from fighting fires to predictable inventory management, and their profit margins soared.

The slow degradation of quality often begins with small, undocumented changes—a slightly cheaper component here, a skipped process step there. These minor adjustments, driven by a supplier's internal cost pressure, accumulate over time until they lead to field failures. The common solution—a final inspection before shipment—is fundamentally flawed. It’s a gate, not a system. It might catch a cracked case, but it's powerless against the systemic issues that cause quality fade in manufacturing. By the time a product fails a final check, the resources are already wasted. The true cost isn't just the defective unit; it's the emergency rework, the delayed shipments, and the permanent damage to your brand's reputation.

The Myth of Final Inspection

Relying solely on final inspection is like trying to prevent a house fire by installing a smoke detector in the mailbox. A truly robust system prevents the fire from ever starting in the first place.

So, What Does a Proactive Quality Assurance (PQA) System Actually Look Like?

You’re trying to diagnose a field failure, but your supplier can’t tell you which batch of raw materials was used or which operator assembled the unit. This lack of transparency makes problem-solving impossible and leaves you completely exposed.

A robust PQA system isn't a vague promise; it's a tangible framework of documented procedures that govern every stage of the massager manufacturing process. It’s designed to make quality repeatable and predictable. Our PQA is built on three core pillars that work together to eliminate inconsistency and give you complete confidence.

Pillar 1: Absolute Traceability

From the moment raw materials enter our warehouse to the final shipment, every single component is tracked. We use a lot-and-batch control system that links every finished massager to the specific batches of motors, fabrics, and electronic boards used to build it. If a field failure ever occurs, we can perform a root cause analysis in hours, not weeks, and instantly isolate any other affected units.

Pillar 2: In-Process Controls & SPC

We don’t wait until the end to check for quality; we build it in at every step. Key process parameters—like motor torque and heat element temperature—are monitored in real-time using Statistical Process Control (SPC). This is your statistical guarantee that the 10,000th unit will function identically to the first because we can detect and correct any minor deviations before they become defects.

Pillar 3: Rigorous Change Control (ECN)

This is your shield against "Quality Fade." Nothing changes without a formal Engineering Change Notice (ECN) process. Every single modification is documented, tested, validated, and, most importantly, approved by you *before* it's implemented. This guarantees that you will never receive a product made with different materials or processes than the one you originally signed off on.

How Can You Independently Verify a Supplier's Quality System?

The owner of a German physical therapy equipment distributor told me, "Your team didn't just show me a product; they walked me through your FMEA and Control Plan. I chose KLCOSY because I'm not buying a massager; I'm buying a predictable manufacturing process."

That's exactly it. You verify a supplier by auditing their process and demanding objective evidence. Supplier quality management should start with you asking to see their quality manual and key process documents. Internationally recognized certifications like ISO 9001 are a good baseline, but the ultimate test is to see the system in action. A supplier who is confident in their processes will welcome your audits.

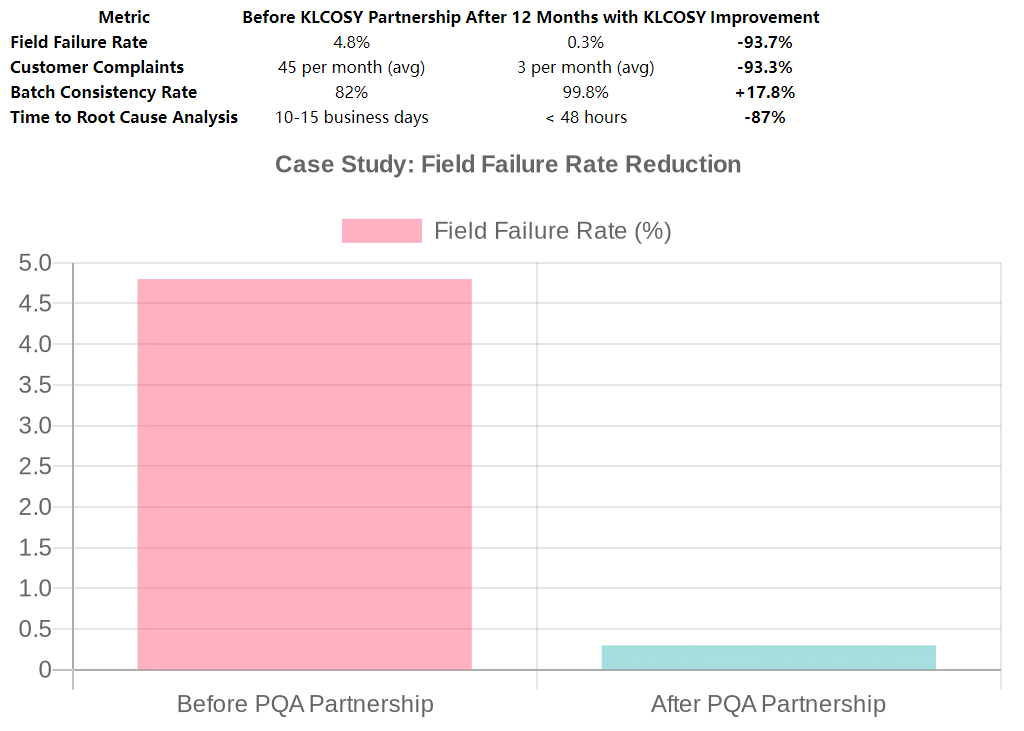

Case Study: German Distributor Reduces Returns by 93%

A premium German distributor was struggling with "Quality Fade" from their previous supplier. After partnering with us and integrating into our PQA system, they saw a dramatic and measurable improvement across the board.

Ultimately, eliminating "Quality Fade" is about shifting from buying a product to investing in a process. Our Proactive Quality Assurance system is designed to de-risk your business by delivering verifiable consistency. A reliable manufacturing partner shouldn't just sell you a product; they should offer a transparent and auditable system that guarantees quality for the long term. This is how we ensure our quality control for massagers is second to none.